Automated calibration for maximum process safety

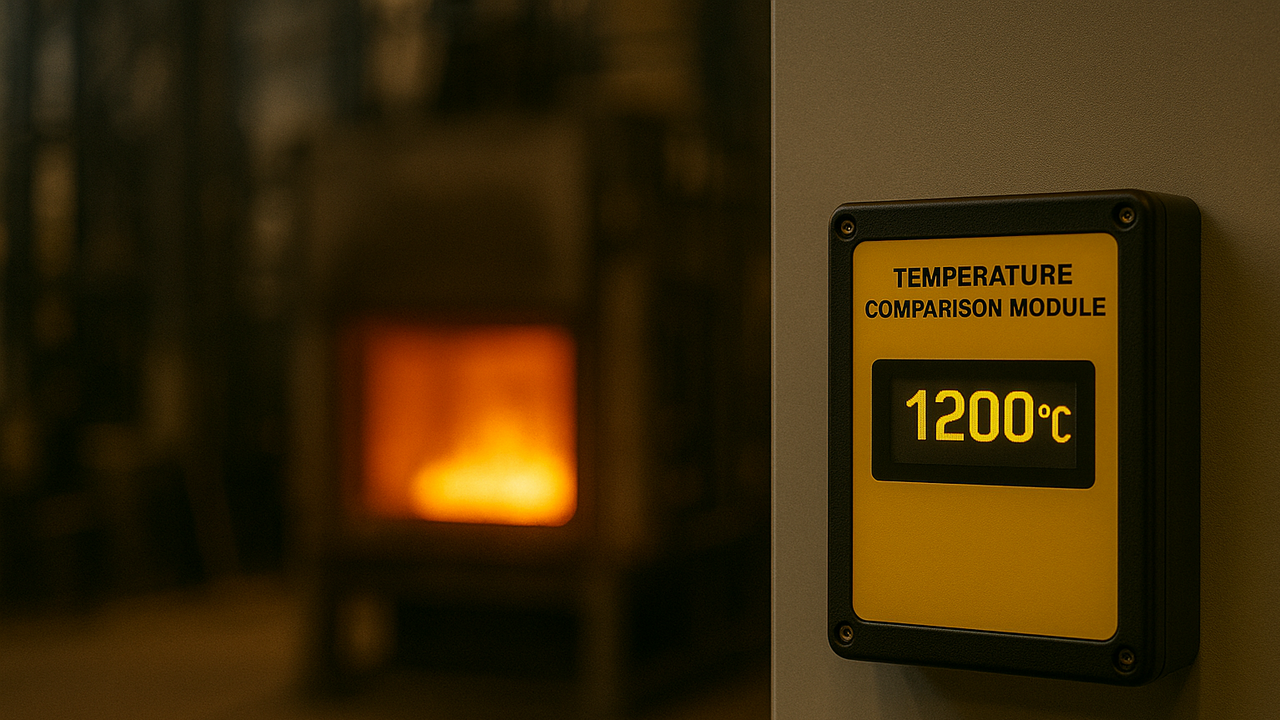

Implement temperature monitoring with the TCM Temperature Comparison Module in compliance with standards and efficiently.

With the TCM Temperature Comparison Module, we offer you a solution for automated calibration and temperature monitoring that is specifically designed to meet the requirements of industrial heat treatment processes. Thanks to fully or semi-automated SAT services (System Accuracy Test), thermocouples are checked continuously or at the push of a button – fully compliant with NADCAP, CQI9, AMS, or your individual specification.

Our solution enables easy, visual control of all connected sensors, enhances process safety, and simultaneously reduces the time and cost required for calibrations.

Fully automated SAT verification with A-SAT

Permanently monitored thermocouples – automatic reports in case upon deviation

In A-SAT mode, the TCM compares fixed dual thermocouples at minute intervals. Deviations from the specified tolerance range result in the automatic generation of a PDF report with immediate email notification. This ensures that no deviation goes unnoticed while simultaneously meeting all relevant standards and audit requirements.

Thanks to the potential-free relay output, additional local signaling can occur – for example, to control external systems or to send direct alerts to the operating personnel.

Compliance with standards

With the TCM module, you reliably and transparently meet all requirements for NADCAP, CQI9, and AMS compliance.

Automation of calibration processes

The automatic calibration of your thermocouples reduces effort and ensures consistent measurement quality.

Time savings in temperature testing

Thanks to automated processes, you save time on every temperature check and avoid manual inspection efforts.

Reliability of measurement values

Continuous monitoring improves the reliability of measurement results and minimizes the risk of erroneous values.

Integration into existing systems

The TCM can be easily integrated into your existing infrastructure and used directly via standard interfaces.

Data recording and report sending

All measurement values are automatically recorded, stored, and sent via email as a standard-compliant report.

Flexible use through app control

With the mobile device app, you can initiate calibration processes directly on-site – easily, quickly, and usable anywhere.

Cross-location use

With centralized cloud storage, you can access your data across locations – securely and available at any time.

Semi-automatic SAT process with S-SAT

App-based calibration start and intelligent data comparison

The S-SAT mode allows for quick and secure calibration by comparing a connected thermocouple with a stored calibration table. The calibration process is initiated either via the dibalog app or automatically triggered by plugging in a calibrated thermocouple through the mini plug connection (E2).

The TCM module automatically captures all relevant measurement data, generates a compliant report, and also sends it automatically via email. All processes are fully compatible with NADCAP, AMS, and CQI9.

Scalable architecture for flexible applications

Modular, group-capable, and ready for cloud services.

The TCM module can be easily integrated into existing structures. As a master module, it takes over the central data storage as well as the report generation for defined groups. Thanks to the cloud connection – locally or in the web cloud – your calibration data is available anytime and anywhere.

The calibration tables can be automatically shared between multiple TCMs. Simple configuration and support for all common thermocouple types complete the modular concept.

Technical details at a glance

Highest precision and user comfort – ready for industrial use

The TCM Temperature Comparison Module has been specifically designed for industrial continuous operation. It combines robust hardware, an intuitive app control, and a future-proof communication architecture:

Measuring range: 0 to 1500 °C

Languages: German, English | Units: °C, °F

Communication: TCP/IP

Storage: MicroSD (16 GB, Master: 32 GB)

Thermocouple types: freely configurable according to customer specifications

Inputs: E1 + E3 (fixed), E2 (pluggable via mini connector)

Outputs: 1× potential-free relay

App: Android and iOS

Cloud Services: local or web-based

All functions are designed for reliability, efficiency, and scalability. Thus, the TCM module is the ideal complement for your operational optimization in energy management.

Summary: TCM Temperature Comparison Module – Operational Optimization

- TCM Module

Automates the calibration of thermocouples and ensures continuous temperature monitoring. - A-SAT

Fully automated comparison of dual thermocouples with automatic report generation upon deviation. - S-SAT

Semi-automatic calibration by comparison with a calibration table, controlled via app or plug connection. - Compliance with Standards

Supports NADCAP, AMS, and CQI9 as well as individual specifications. - Data Management

Reports are automatically generated, saved, and sent via email. - System Integration

Easy to integrate thanks to TCP/IP communication, standard interfaces, and configurable inputs and outputs. - Cloud Connectivity

Local or web-based data storage with access options across multiple locations. - Mobile Control

App for Android and iOS allows flexible use on-site.